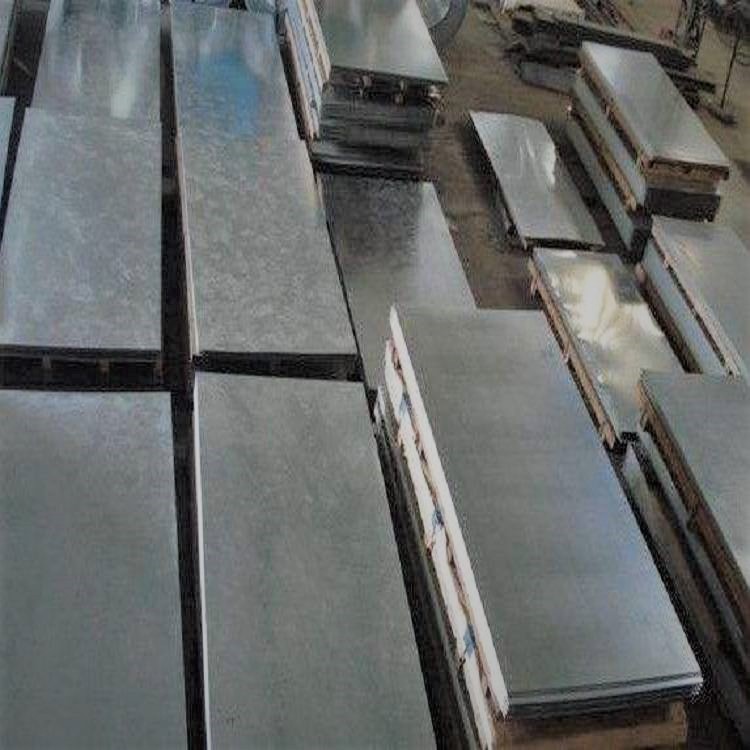

Alloy galvanized sheet

Short Description:

Galvanized sheet refers to the steel plate with a layer of zinc on the surface. Galvanizing is an economic and effective rust prevention method often used. About half of the world’s zinc production is used in this process.

It can be divided into the following categories according to production and processing methods:

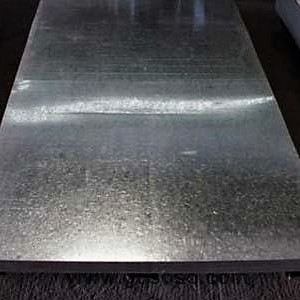

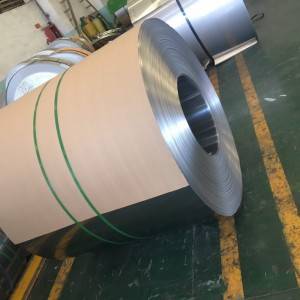

① Hot dip galvanized steel plate. The steel sheet is immersed in the molten zinc bath so that a layer of zinc is adhered to its surface. At present, the continuous galvanizing process is mainly used, that is, the rolled steel plate is continuously immersed in the zinc melting bath to make the galvanized steel plate;

② Alloyed galvanized steel sheet. This kind of steel plate is also made by hot dip method, but it is heated to about 500 ℃ immediately after coming out of the groove to form an alloy film of zinc and iron. The galvanized sheet has good coating adhesion and weldability;

③ Electro galvanized steel sheet. The galvanized steel sheet produced by electroplating has good workability. However, the coating is thin and the corrosion resistance is not as good as that of hot dip galvanized sheet;

④ Single side plated and double side poor galvanized steel sheet. Single side galvanized steel plate, i.e. products galvanized only on one side. It has better adaptability than double-sided galvanized sheet in welding, coating, antirust treatment and processing. In order to overcome the disadvantage of not coating zinc on one side, there is another kind of galvanized sheet coated with thin layer of zinc on the other side, that is, double-sided poor galvanized sheet;

⑤ Alloy, composite galvanized steel sheet. It is an alloy made of zinc and other metals such as aluminum, lead and zinc, and even a composite plated steel plate. This kind of steel plate not only has excellent antirust performance, but also has good coating performance;