steel pipe - Manufacturers, Suppliers, Factory from China

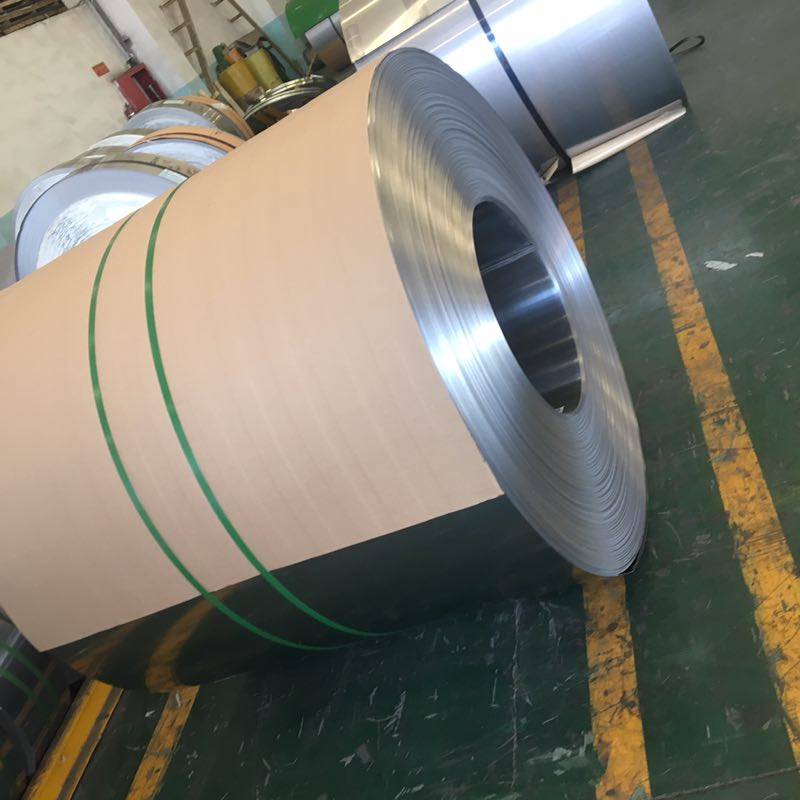

Our solutions are widely regarded and trustworthy by consumers and may meet continually modifying financial and social requirements for steel pipe, Welded Forged Flange, Hot Rolled Steel Plate, A182 F321 Flanges,Steel Welded Pipe. Welcome to visit our firm and factory. Be sure to come to feel free to get in touch with us in case you need any additional assistance. The product will supply to all over the world, such as Europe, America, Australia,Benin, Ghana,Philippines, Argentina."Make the women more attractive "is our sales philosophy. "Being customers' trusted and preferred brand supplier" is the goal of our company. We've been strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

Related Products